Blog

- Home

- Cable Tray

- Choosing the Right Cable Tray for Your Electrical Systems

Choosing the Right Cable Tray for Your Electrical Systems

Selecting the appropriate cable tray for your electrical systems is an essential decision that should not be taken lightly. Cable trays serve as mechanical support systems, providing a robust structure for various electrical components such as cables, raceways, and insulated conductors. They are a reliable alternative to wireways and electrical conduits, as they offer an open design that facilitates efficient power distribution, control, signal instrumentation, and communication.

When it comes to cable tray materials, there are several options available. Metal cable trays, including galvanized steel, stainless steel, and aluminum, offer excellent durability and strength. On the other hand, non-metallic cable trays made of glass-fiber reinforced plastic provide resistance to corrosion and are suitable for environments where non-conductivity is required.

The primary purpose of cable trays is to support and protect power and communication cables while allowing for easy upgrading, expanding, reconfiguring, or relocating of networks. Unlike enclosed wireways and conduits, cable trays offer better heat dissipation, reducing the risk of overheating and electrical malfunctions. Additionally, the open design allows for convenient access during replacement and repair tasks, minimizing downtime and ensuring efficient maintenance.

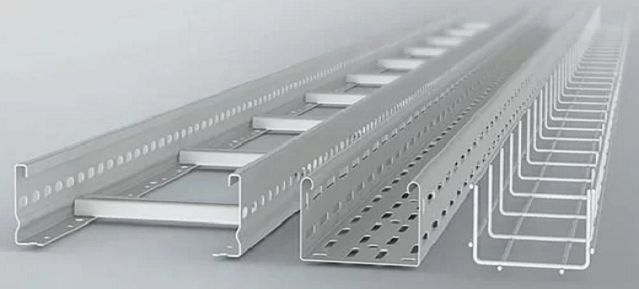

The selection of the right cable tray type depends on various factors, including the number of cables, their size, spacing, and weight. Let’s explore some popular cable tray types:

- Ladder-type Cable Tray: This type features two side rails connected by rungs, providing easy accessibility to cables from the top or bottom. The rungs also serve as anchors for securing cables, whether in non-horizontal or horizontal tray runs.

- Perforated Cable Tray: With a ventilated bottom and side rails, perforated cable trays offer increased cable support compared to ladder-type trays. They are suitable for applications that require improved cable ventilation and additional structural support.

- Solid-bottom Cable Tray: Solid-bottom trays are ideal for fiber optic cable installations, where cable drooping could negatively impact system performance. Moreover, solid-bottom trays are chosen to mitigate electromagnetic and radio-frequency interference.

- Wire Mesh Cable Tray: Constructed by welding stainless steel wires together, wire mesh trays resemble baskets and are commonly used for supporting low voltage, telecommunication, and fiber optic cables over shorter spans.

- Channel Cable Tray: As a basic metal tray, channel cable trays are typically employed in small-scale cable installations. They provide a simple yet effective solution for organizing and supporting cables.

When deciding which cable tray to use, it is crucial to consult with engineers or designers who can assess the project’s specific requirements and environmental conditions. This ensures that the chosen cable tray type offers optimal functionality, durability, and compatibility with the electrical systems.

While cable trays offer numerous advantages, such as cost-effectiveness and easy maintenance, it is important to be aware of potential drawbacks. For instance, solid-bottom cable trays may face moisture buildup, which can affect the cables’ integrity over time. Regular inspections and preventive measures are necessary to mitigate any risks associated with this issue.

At Beniko Cable Tray Factory, we take pride in offering top-of-the-line cable tray solutions tailored to meet your specific needs. With our unwavering commitment to quality and customer satisfaction, we are your trusted partner for all your electrical system requirements.

Contact us today to discuss your cable tray needs. Let us show you why we are the preferred choice for discerning customers seeking top-quality cable tray solutions. Beniko Cable Tray Factory – your trusted partner for all your electrical system requirements.