Description

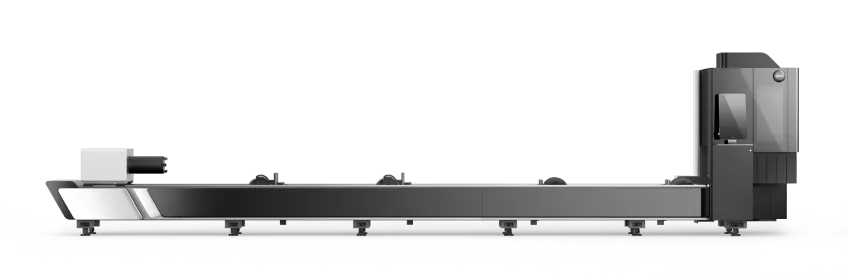

Bodor K-Series – Entry-Level Tube Laser Cutting Machines

The K-Series offers efficient tube cutting with high-speed loading (up to 100m/min) and enhanced automation via optional K-Loader and K-Trans systems. Simplified operation allows automatic workpiece generation and rapid processing, making it ideal for industries like cabinetry, construction, and mechanical processing.

| Model | k5 | k3 | k2 | k1 | K0 |

|---|---|---|---|---|---|

| Maximum machinable tube length | 12000mm | 6500mm/9200mm/12000mm | 6500mm/9200mm | 6500mm | 6500mm |

| laser Power | 12kW/6kW | 6kW/3kW | 6kW/3kW/1.5kW | 3kW/1.5kW | |

| Round tube size range | φ150-φ500mm | ф25-ф356mm | φ8-φ230mm | φ6-φ120mm | φ6-φ90mm |

| Square tube size range | φ150-φ500mm | ф25-ф356mm | φ8-φ230mm | φ6-φ110mm | φ6-φ90mm |

| Rectangular tube Side length | 500mm≥Side length≥150mm | 356mm≥Side length≥25mm | 230mm≥Side length≥8mm | 110mm≥Side length≥6mm | 90mm≥Side length≥6mm |

Cut costs, not quality

-

Speed improved

The K series achieves a maximum loading speed of 100m/min and a chuck rotation speed of 150r/min. It realizes rapid cutting without compromising on cutting speed.

-

Automation enhanced

The optional loading devices, K-Loader and K-Trans, are available to boost customers’ automation level, accelerate the loading speed and increase processing efficiency.

-

Production simplified

The corresponding workpiece graphics can be automatically generated simply by entering data. Centering, edge detection, cutting and unloading can be completed with just a few clicks.

Applicable Industries

Widely applied in industries such as chassis cabinets, ventilation ducts, door and window manufacturing, construction materials, kitchen and bathroom manufacturing, mechanical processing and other industries.