Blog

- Home

- Cable Tray

- Unleashing the Power of Cable Tray Systems

Unleashing the Power of Cable Tray Systems

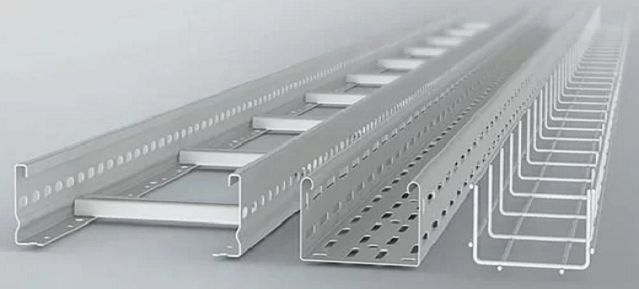

In the dynamic world of commercial and industrial applications, cable tray systems stand as indispensable tools, providing vital structural support for cables. These systems come in various styles, each designed to cater to specific needs and applications. In this comprehensive overview, we will explore the distinct features, benefits, and applications of five prominent cable tray types: Ladder-type Cable Tray, Perforated Cable Tray, Solid-bottom Cable Tray, Channel Cable Tray, and Wire Mesh Cable Tray.

Ladder-type Cable Tray: Ladder-type Cable Trays are renowned for their sturdy construction and versatility. They consist of two longitudinal side rails connected by individual rungs, creating a ladder-like structure. This design allows for excellent cable support and easy installation. Key features and benefits of ladder-type cable trays include:

- Strength and Durability: Ladder-type cable trays are engineered to withstand heavy loads and harsh environments. They offer exceptional strength while maintaining a lightweight design.

- Easy Cable Routing: The open design of ladder-type trays enables easy cable routing and access. Cables can be easily laid in or removed from the trays at any point, facilitating efficient installation and maintenance.

- Airflow and Heat Dissipation: The perforated rungs and side rails of ladder-type trays promote airflow, preventing heat buildup and ensuring optimal performance of cables.

- Customization: Ladder-type trays are available in various widths, heights, and lengths, allowing for customized configurations to meet specific project requirements.

Perforated Cable Tray: Perforated Cable Trays feature a solid bottom with evenly spaced perforations on the sidewalls. This design allows for effective cable support while facilitating proper airflow and heat dissipation. Key features and benefits of perforated cable trays include:

- Enhanced Cable Ventilation: The perforations on the sidewalls enable airflow, preventing heat accumulation and ensuring cable longevity.

- Cable Management and Protection: Perforated trays provide efficient cable management, allowing for easy attachment and organization of cables. They also offer protection against external factors, such as moisture and dust.

- Strength and Flexibility: Perforated cable trays are available in various materials and thicknesses, ensuring durability and flexibility for different application requirements.

Solid-bottom Cable Tray: Solid-bottom Cable Trays, also known as non-perforated trays, feature a fully enclosed design with a solid base. These trays offer consistent support and protection for cables. Key features and benefits of solid-bottom cable trays include:

- Continuous Cable Support: The solid base of these trays ensures uninterrupted support for cables, reducing the risk of sagging or damage.

- Cable Protection: The enclosed design of solid-bottom trays provides enhanced protection against environmental factors, such as dust, moisture, and chemical exposure.

- Versatility and Load Capacity: Solid-bottom cable trays are available in various materials, thicknesses, and load ratings, catering to a wide range of applications with different load requirements.

Channel Cable Tray: Channel Cable Trays feature a U-shaped cross-section, resembling an open channel. This design provides excellent cable support and protection while allowing for easy cable installation and maintenance. Key features and benefits of channel cable trays include:

- Easy Cable Access: The open channel design of these trays allows for quick and convenient cable routing, additions, and modifications.

- Cable Security: Channel trays provide secure cable containment and protection, minimizing the risk of cable damage or interference.

- Adaptability and Customization: Channel cable trays come in various sizes and configurations, allowing for easy adaptation to different installation requirements. They can be modified or combined to create turns, junctions, and transitions.

Wire Mesh Cable Tray: Wire Mesh Cable Trays are constructed from high-strength steel wire welded into a mesh pattern. This unique design offers several advantages, making wire mesh trays a popular choice for various applications. Key features and benefits of wire mesh cable trays include:

- Efficient Cable Ventilation: The open mesh pattern ensures continuous airflow, preventing heat buildup and allowing for efficient cooling of cables.

- Cable Visibility and Identification: The open design of wire mesh trays allows for easy cable identification, troubleshooting, and maintenance.

- Lightweight and Easy Installation: Wire mesh trays are lightweight yet robust, making them easy to handle and install. They often feature simple interlocking systems or easy assembly mechanisms.

- Flexibility and Adaptability: Wire mesh trays offer versatility in terms of customization and adaptability. They can be easily modified on-site to accommodate changing cable routing requirements.

In conclusion, cable tray systems are indispensable components of modern electrical installations. Whether it’s the sturdy construction of ladder-type trays, the efficient cable ventilation of perforated trays, the consistent support of solid-bottom trays, the flexibility of channel trays, or the airflow and visibility provided by wire mesh trays, each type offers unique features and benefits to meet specific project needs. By selecting the appropriate cable tray system for your application, you can ensure efficient cable management, optimal cable performance, and enhanced safety in your commercial or industrial setup.