Blog

- Home

- Laser Cutting

- Maintaining Your Laser Cutter for Optimal Performance: Share tips on cleaning, calibration, and routine maintenance to extend the life of your equipment.

Maintaining Your Laser Cutter for Optimal Performance: Share tips on cleaning, calibration, and routine maintenance to extend the life of your equipment.

Introduction

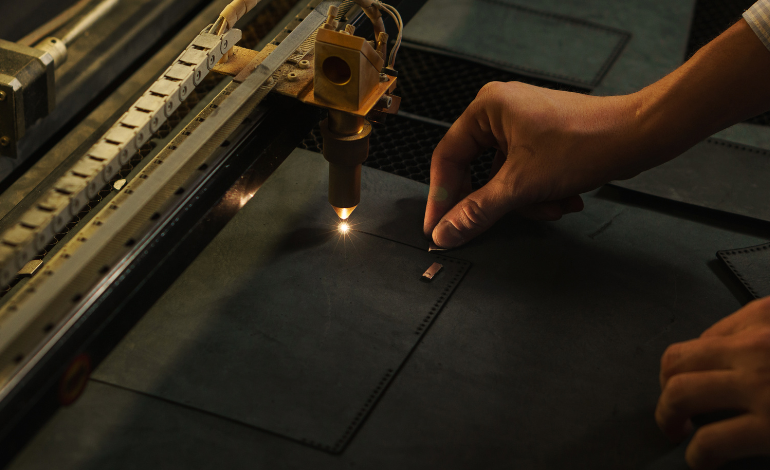

Your laser cutter – the magician, the sculptor, the precision-cutting powerhouse. But even the most dazzling magic show needs a well-maintained act. To keep your laser humming like a finely tuned engine and churning out masterpieces, regular maintenance is key. This post dives into the essential tips for cleaning, calibration, and routine care, maximizing your laser’s lifespan and ensuring it stays a loyal member of your creative toolset.

Cleaning: Banishing the Dust Bunnies of Destruction

Think of dust bunnies as miniature saboteurs lurking in your laser cutter, waiting to wreak havoc on lens clarity and beam accuracy. Regular cleaning is your counteroffensive. Here’s your battle plan:

Lens Love: Your lens is the heart of the operation. Invest in a dedicated lens cleaning kit (microfiber cloths and lens cleaning solution) and gently wipe both sides after each use. For stubborn grime, use lens cleaning wipes dampened with the solution. Avoid alcohol or abrasives – they’re more likely to harm than help.

Mirror Mania: Mirrors, just like lenses, crave a dust-free environment. Use clean cotton swabs and compressed air to dislodge any dust particles. Remember, even a tiny speck can affect beam precision.

Vacuum Venturing: Don’t forget the hidden nooks and crannies! Regularly vacuum the exhaust system and internal compartments to prevent dust buildup, which can hinder airflow and performance.

Calibration: Keeping the Cut Sharp

Even the most skilled fencer needs their blade calibrated. For your laser cutter, that means keeping the beam aligned and focused for accurate cuts. Here’s how to keep it on point:

Self-Test Savior: Most laser cutters have built-in self-test functions. Run them regularly to identify any misalignments and follow the manufacturer’s instructions for adjustment.

Paper Power: Print a test pattern and analyze the cuts. Is it symmetrical? Are the edges clean? If not, it’s time for a manual calibration procedure. Refer to your manual for specific instructions, but it often involves adjusting internal mirrors and screws.

Professional Precision: If things get too technical, or you simply prefer peace of mind, consider professional calibration by a certified technician. They have the expertise and tools to ensure your laser cuts with razor-sharp precision.

Routine Maintenance: The Preventative Potion

Just like your car needs an oil change, your laser cutter needs its own care routine. Here are some essential practices:

Water Watcher: Ensure proper water circulation by checking the water level and filter in your chiller regularly. Change the filter according to the manufacturer’s recommendations. Clean water and good filtration are crucial for laser beam stability and component longevity.

Lubrication Love: Consult your manual for lubrication points and schedules. Regularly applying a light machine oil to moving parts keeps things running smoothly and prevents premature wear and tear.

Air Aware: Check and clean the air filter of your compressor regularly. Clean air minimizes dust and debris entering the laser system, extending component life and enhancing cut quality.

Conclusion: Invest in Care, Reap the Rewards

By incorporating these simple but essential maintenance practices into your routine, you’ll ensure your laser cutter stays in tip-top shape and continues to bring your creative visions to life. Remember, a well-maintained laser is a happy laser, and a happy laser means endless possibilities for your artistic and professional endeavors. So, grab your cleaning kit, calibrate your focus, and let your laser work its magic!