Description

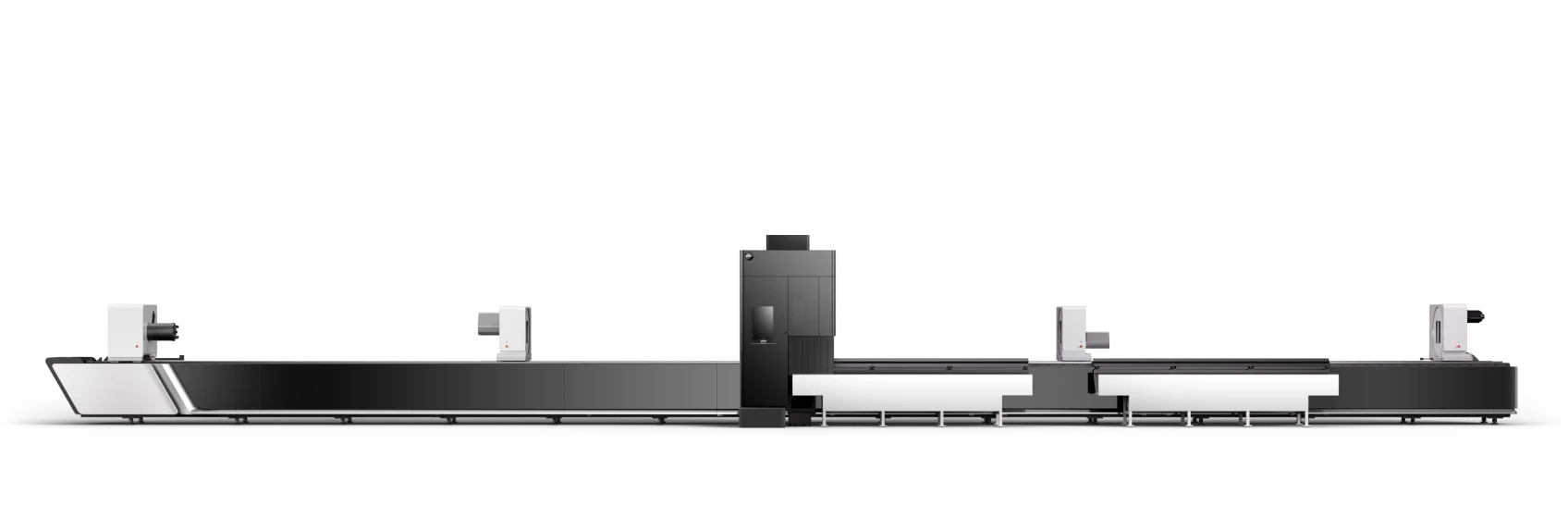

Bodor M-Series – Fiber Laser Metal Tube Cutting Machines

The M-Series provides high-precision, hands-free tube cutting for tubes up to 530 mm in diameter. With efficient simultaneous cutting, loading, and unloading, it minimizes waste and enhances productivity. The 4-chuck mechanism ensures safety, while excellent loading capacity meets demanding metal tube processing needs.

| Model | M5 | M3 | M2 |

|---|---|---|---|

| Maximum machinable tube length | 6500mm/9200mm/12000mm | ||

| laser Power | 12kW/6kW | 6kW/3kW | 6kW/3kW/1.5kW |

| Round tube size range | ф80-ф510mm | ф25-ф356mm | ф8-ф230mm |

| Square tube size range | ф80-ф510mm | ф25-ф356mm | ф8-ф230mm |

| Rectangular tube Side length | 510mm≥Side length≥80mm | 356mm≥Side length≥25mm | 230mm≥Side length≥8mm |

High efficiency for different work cases

-

Safety enhancement

Provide a secure operating environment. M5’s 4-chuck mechanism ensures high-quality cutting without manual intervention, ensuring a hands-free operating environment with lower human costs.

-

Excellent loading capacity

Fulfill diverse, hard-core cutting needs. Ideal for heavy metal tube processing, M5 gives you the ability to cut tubes with diameters up to 530 mm.

-

0 excess material processing

Minimize manufacturing waste from the source. During operations, M5 will help you utilize every piece of material to the largest extent possible, reducing waste and improving cost-effectiveness.

Simultaneous Cutting, Loading and Unloading

The M Series completely revolutionizes the process and efficiency. When cutting tubes, it can simultaneously initiate a new round of loading or finish the previous unloading, bringing about an unprecedentedly efficient and smooth processing experience.