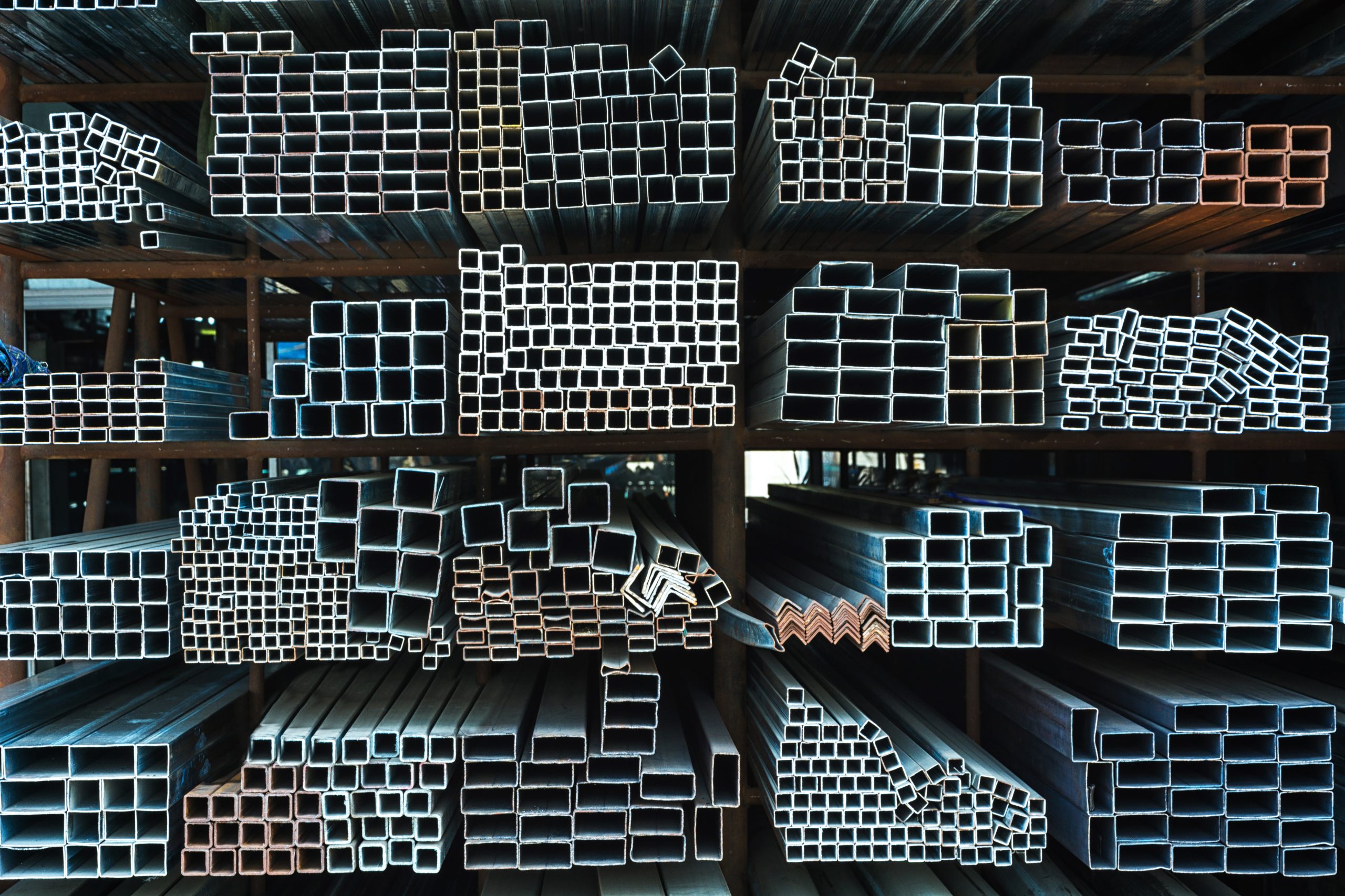

STEEL TYPES USED IN FABRICATION

You will have to choose between a lot of different options when choosing a fabric to utilize for building, engineering, or other types of projects. But one option that is frequently used to make goods across all entirely distinct forms of materials is steel. Steel is widely used because there are so many different types available. Because each steel grade has unique qualities, four main categories of steel are typically distinguished from them by online steel suppliers.

The Get A Beam team is a steel consulting firm that works with domestic steel manufacturing companies to supply the necessary materials for several construction projects. Nonetheless, we frequently notice that many of our clients are far more confused about the differences between different types of steel when attempting to purchase steel online, therefore our advisors have produced this guide to help.

Basics of Fabricating Steel. Iron and carbon together form the basic composition of steel, which is an alloy. In addition to its high strength-to-weight quantitative ratio, durability, and sporadic resistance to corrosion, steel is made up of a variety of components.

Steel fabrication is the process of transforming raw steel into prefabricated shapes that may be assembled to create the desired result. Fabricating steel is a highly skilled endeavor, with skilled artisans keen to understand how to combine disparate methods to get the most straightforward final product.

Which Square Is Used To Measure Different Types Of Steel?

Over 3500 distinct steel grades are already in existence as a result of impurities and additional alloying components that will be added. These factors contribute to the variability in steel grades. It would be nearly difficult for anyone other than steel fabricators and consultants to handle this enormous array of steel grades. comprehend, but fortunately the grades are broadly divided into four types of steel.

Tool Steel:

Tool steels are typically used to construct metal instruments, such as hammers. This type of steel is particularly well-suited for toolmaking since tool steels are both heat- and scratch-resistant, and its enhanced durability is achieved by adding elements such as metal or atomic number 74.

Tempering, which entails applying heat, rapidly chilling the steel, and then heating it again, is frequently used to create alloy steel. This develops a difficult-to-beat level of strength and resistance.

Carbon Steel:

This type of steel, which is the purest, is mostly made of carbon and iron, with a significant amount of other alloying elements. In general, steel has a dull, matte appearance and is susceptible to corrosion. Based on the amount of carbon included in the alloy, there are three different types of steel:

Low Carbon/Mild Steel: Soft-cast steel has a carbon concentration of about 0.3%, which gives it the ability to stretch under load. This is typically used to make pipes, bolts, and cables.

Medium Carbon: Medium steel often has a carbon concentration of 0.6% or less, which makes it less flexible but stronger overall. For this reason, it works well for making things like railroad tracks.

High Carbon: High carbon steel has a carbon content of about 1.5% (but never quite two percent), which gives it an extra layer of strength and makes it perfect for creating sharp cutting tools.

Stainless Steel:

Whether or not they have experience working with steel, the majority of people have spotted this type of steel. Usually, When corrosion resistance is of utmost importance, stainless steel, which normally has 10–20% part metal as an alloying element, is frequently used in steel fabrication. The common goods made from stainless steel fabrication include medical instruments, food processing tools, and cutting tools. Because stainless steel is such a versatile material, there are more than a hundred distinct grades within this single subtype of steel.

You may read more about steel grades by visiting this blog post from Getting A Beam.

Alloy Steel:

As the name implies, this group of steel is categorized according to various alloying elements, such as copper, aluminum, and nickel. These extra alloying components will add a variety of qualities according on what is required, such as strength, weldability, and corrosion resistance.

Steel Fabrication Services

The Obtain A Beam look will make it easier if you want to get steel from any of the four steel designs that are described above. It’s an easy way to place an online order for steel from local steel fabricators. Please feel free to contact the United States of America with any questions you may have going forward; we would be pleased to help.

Building a wide variety of products, such as cabinets, fire pits, racks, storage units, and trophies, out of entirely different raw materials requires metal fabrication. A variety of techniques, including cutting, bending, and collecting, are used in the process. important considerations square measure specified for the cloth to be used, supporting your standards and the quality required for the best output. Choose knowledgeable professionals to create entirely new metals based on your needs.

In addition, we often focus on metal art, welding, CNC machining, hydraulics, and on-site repairs. Putting the pieces together for our customers since 1996. In addition, we often focus on metal art, welding, CNC machining, hydraulics, and on-site repairs.

Steel has several benefits when it comes to being used in construction.

Stainless steel is resistant to marking and corrosion. It has Cr, which causes steel’s surface to naturally form a Cr compound layer. The film comes into contact with O when chrome steel is exposed to harmful conditions, shielding the metal’s surface.

In order to increase the corrosion resistance of steel, manufacturers incorporate substitute materials. Certain weathering elements, such as nickel, atomic number 7, and molybdenum, yield more than sixty distinct grades of chrome steel.

Compared to various other materials, stainless steel is more heat resistant. It is fillable to a range of comes because it will generate distance without sacrificing strength.

Steel also has a positive environmental impact. It may be recycled repeatedly without losing its quality or strength.

Products are usually fabricated from chrome steel’s properties create it a superb alternative for the subsequent products:

Furnace components: Once heated, chrome steel resists. It’s a sincere substitute for boiler room lining, chamber components, and oven lining.

Equipment exposed to acid: When exposed to acid, stainless steel doesn’t corrode and keeps its strength.

Equipment used close to the water: Coastal homes and instruments are made of chrome steel. Boat elements such as mechanical device shafts and instrumentality housing are made of steel. Chrome steel is a reliable substitute for instruments connected to ship hulls and permanently submerged pumps since it even holds up when submerged.

Tanks: When choosing a material for tanks that store chemicals, gases, liquids other than water, chrome steel might make sense. It doesn’t have to be thick to be strong, and it is adaptable. It is resistant to rust and other types of corrosion that develop when a material is frequently exposed to liquids. Tanks with an industrial capacity can store thousands of gallons. Tanks made of chrome steel are used by waste management services, food companies, pharmaceutical companies, and farmers.