Enhance the durability and aesthetics of your products with our professional powder coating services. With a wide range of colors and finishes available, we can customize the appearance of your metal components to suit your design preferences.

BENIKO offers professional powder coating services to enhance the durability, aesthetics, and functionality of your metal products. Our state-of-the-art powder coating facility and experienced team ensure high-quality finishes that meet the highest industry standards. Whether you need a single component or a large-scale production run, we have the capabilities to fulfill your powder coating needs with precision and efficiency.

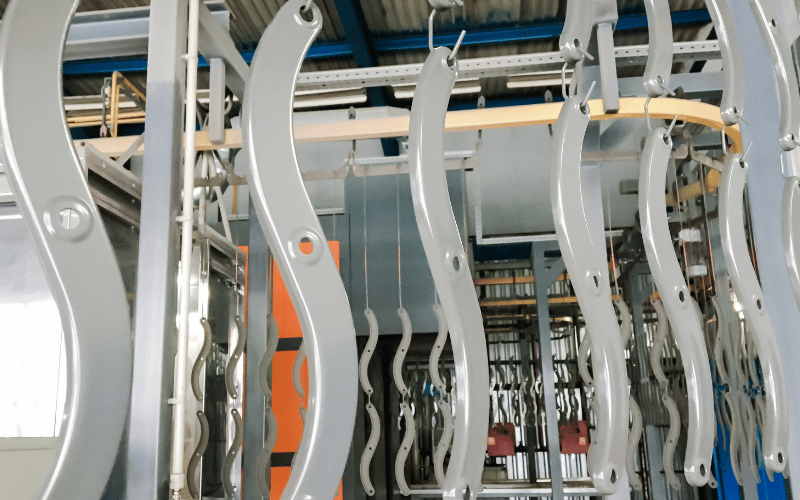

Visit Our Past Powder Coating Projects’ Image Gallery

Our Powder Coating Services Include:

Wide Range of Colors and Finishes: Choose from a vast selection of colors and finishes to achieve the desired look for your products. Our powder coating options include standard colors, metallic finishes, and specialty textures to suit your design preferences.

Durable and Protective Coatings: Our powder coatings provide excellent protection against corrosion, scratches, and UV damage, ensuring long-lasting durability for your metal components, even in demanding environments.

Customized Solutions: We offer customized powder coating solutions tailored to your specific requirements. Whether you need a unique color match or a specialized coating for a particular application, our team can accommodate your needs with precision and attention to detail.

Environmentally Friendly Process: Our powder coating process is environmentally friendly, producing minimal waste and emissions compared to traditional liquid coatings. With no harmful solvents or VOCs, you can trust that your products are coated with an eco-friendly solution.

FAQ

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal surface. The coated part is then cured in an oven, where the powder melts and forms a durable finish.

Powder coating offers several advantages, including durability, corrosion resistance, uniform coverage, and a wide range of color and finish options. It also produces minimal waste and emissions, making it an environmentally friendly coating solution.

Powder coating can be applied to a variety of metal substrates, including steel, aluminum, iron, and galvanized metal.

Powder coating is suitable for a wide range of metals, including steel, aluminum, iron, and galvanized steel. However, some plastics and composites may also be compatible with powder coating.

Powder coating provides a highly durable and protective finish that is resistant to chipping, scratching, fading, and corrosion. With proper maintenance, powder-coated surfaces can retain their appearance and functionality for many years.

The turnaround time for powder coating projects depends on factors such as project size, complexity, and current workload. We strive to complete projects in a timely manner while maintaining high-quality standards.